machining surface finish ra

13 rows Machining Surface Finish. At Xometry Europe we offer four surface roughness levels that are also the values typically specified for CNC Machining applications.

The Difference Between Ra And Rz Production Machining

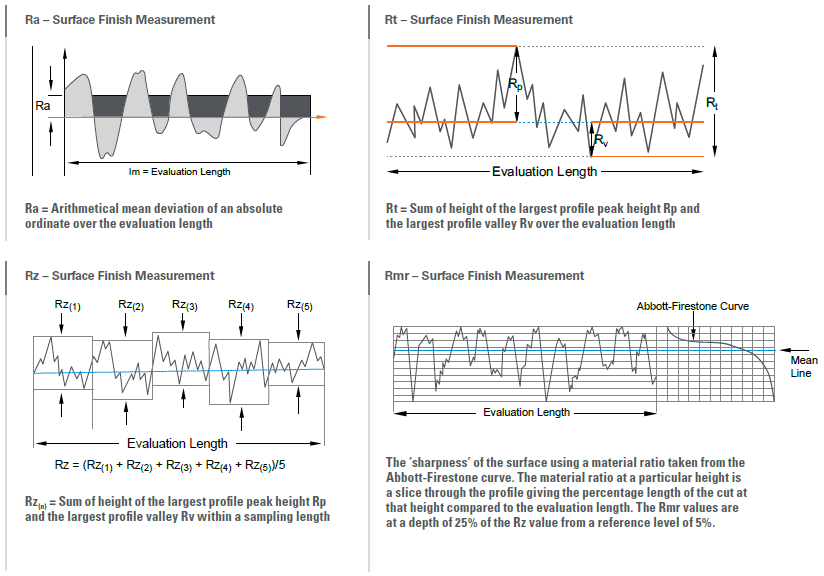

Surface roughness is a calculation of the relative smoothness of a surfaces profile.

. 22 rows Finish Degree. China Ra um China Rz um USA Ra um USA Ra micro. Both Ra and RMS can be expressed in metric or inch.

Nearly infinite capacity for simple and complex jobs. This formula can be used to convert. RMS Microinch Ra0254 X 111.

This high-end surface finish necessitates meticulous attention to detail which adds to the expense. Surface finish Also called sometimes surface roughness is a numeric representation of a surfaces smoothness. The chart lists the name of the finish the roughness in microns and the applications.

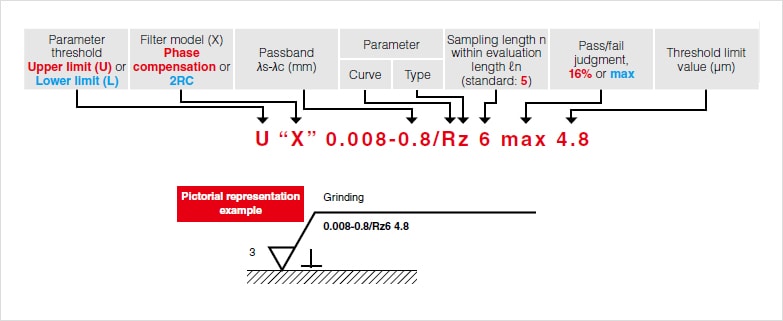

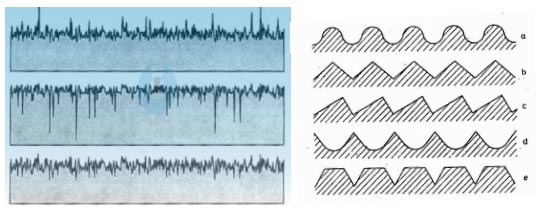

According to an article in Modern Machine Shop written by George Schuetz director of precision gages at Mahr Federal Ra is calculated by an algorithm that measures the average. The roughness of the surface finishing determines how the surface lines and surface quality of the part will appear after it has been machinedSurface finishing means how a mechanical. Surface finish measurement can also be in terms of waviness.

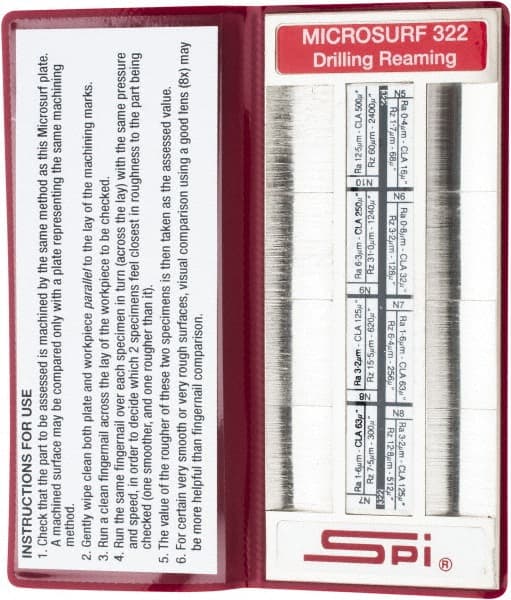

The electropolishing reaction removes material while it improves surface roughness. However it is not uncommon in machine shops for the term surface. There are 3 main ways to acquire the surface roughness value.

When professionals refer to surface finish it is often surface roughness. There is no reliable way to convert between Ra and RMS. Minorly visible tool marks with a standard surface.

Ra microinch RMS microinch Surface Finish Appearance. Because of the material. Get high-quality parts made quickly with Xometrys industry-leading Wire EDM machining service.

Waviness is caused by deflection warping or. Visible machining marks with cutter lines that you can feel. Its essential for parts that are subjected to high levels of stress.

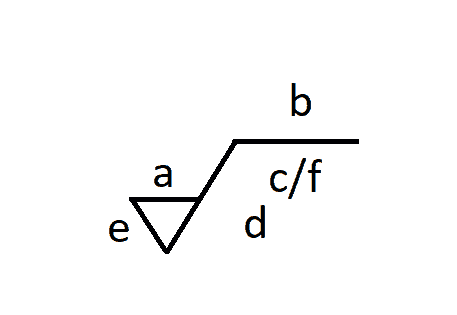

Surface finish is composed of three distinct elements roughness lay and waviness See Figure 1 below. The electropolishing process may improve a surface finish by up to 50. 08 μm Ra.

The plastic surface finish chart is a guide to the various finishes that can be applied to plastic parts.

Surface Finish Quality Ra Rz Rt Surface Roughness Measuring Finish

Spi 0 4 To 12 5 Ra Micro M Surface Finish Nickel Surface Finish Comparator 06558225 Msc Industrial Supply

Surface Roughness Symbol In Drawings Mechanical Engineering General Discussion Eng Tips

Complete Surface Finish Chart Symbols Roughness Conversion Tables

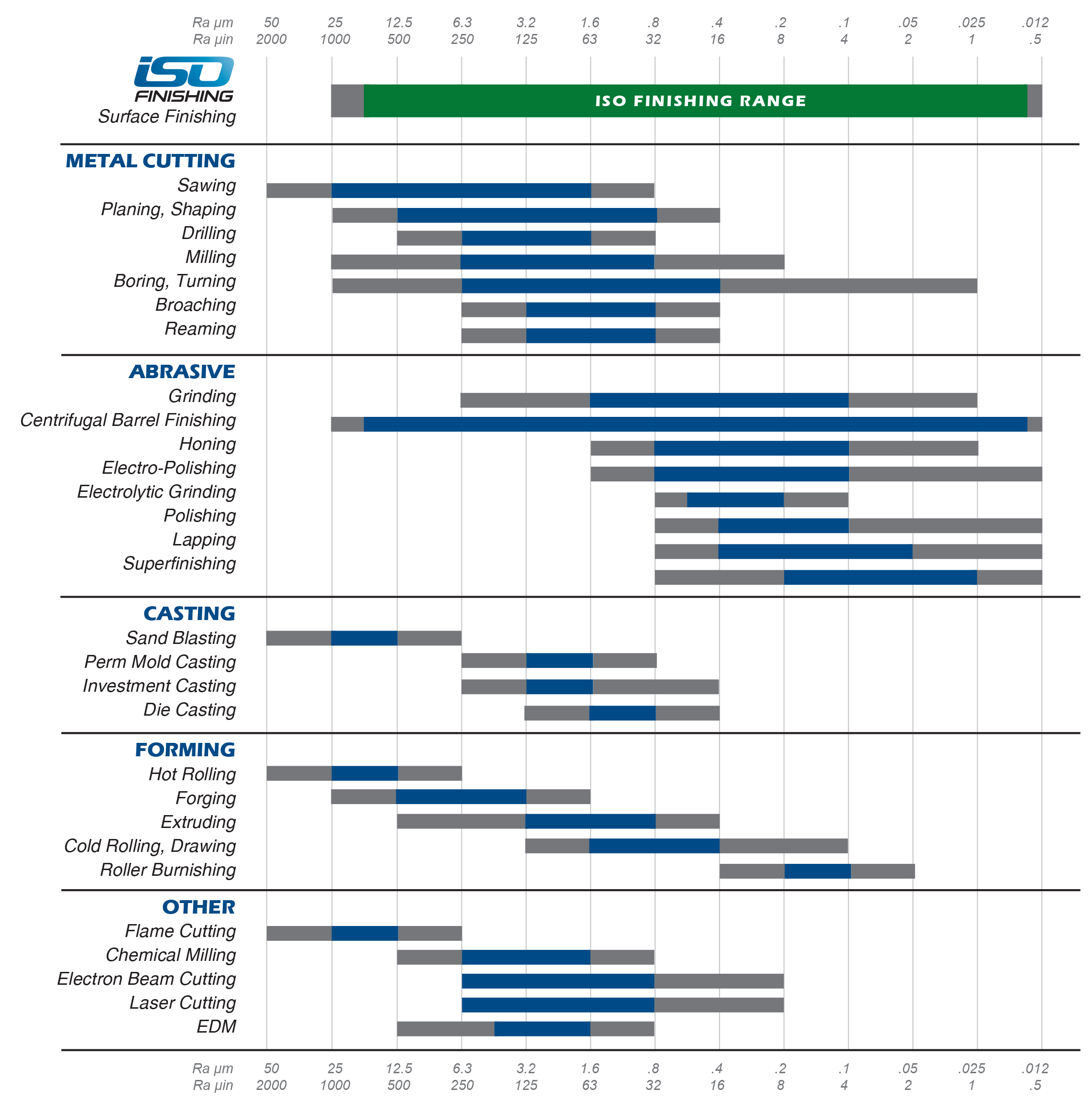

The Only Surface Finishing Chart And Guide You Ll Ever Need

On Machine Surface Finish Measurement Metrology And Quality News Online Magazine

Surface Finish Chart An Precision Engineering

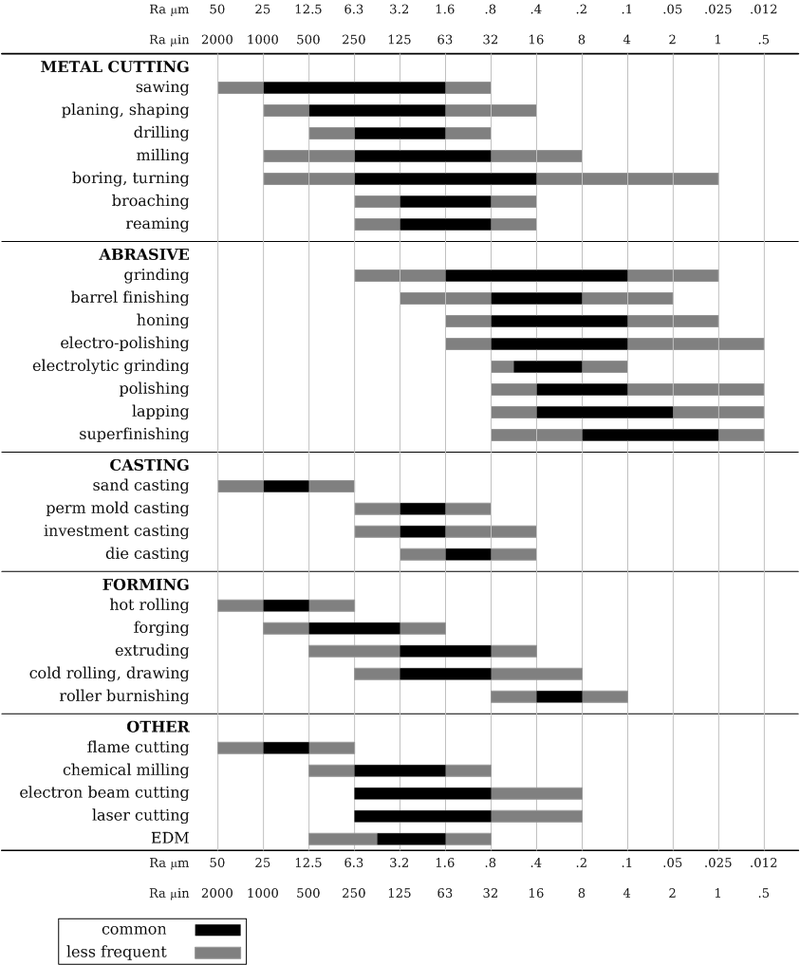

20 Typical Surface Finish For Basic Machining Operations Download Scientific Diagram

The Basics Of Surface Finish Gd T Basics

Machining Surface Finish Chart Conversion Comparator Method Degree Ra Rz Rms

Surface Roughness Chart Comparison Iso Finishing

Measured And The Predicted Values Of Surface Roughness Ra And Rz And Download Table

Typical Ranges Of Surface Finish From Common Machining Processes Download Scientific Diagram

Surface Roughness Finish For Bearings And Seals Hallite

Our Surface Finishes Standards For Cnc Machining Hubs

Selecting Right Surface Roughness For Cnc Machining Xometry Europe